贾良玖

博士、长聘教授、博导

招生专业:防灾减灾工程及防护工程 或 智能建造 (报勿填错)

E-Mail:lj_jia@tongji.edu.cn

通讯地址:上海市杨浦区四平路1239号同济大学土木大楼B513室,200092

教育和工作经历

2003–2007 同济大学,土木工程专业,学士

2007–2010 同济大学,结构工程专业,硕士

2008–2009 日本熊本大学,结构工程方向,短期交换留学生

2010–2013 日本东京大学,结构工程方向,博士

2013–2015 日本名城大学,防灾减灾高级研究中心,博士后

2015–2018 同济大学,结构防灾减灾工程系,助理研究员

2018–2023 同济大学,结构防灾减灾工程系,副教授

2023-2024 同济大学,结构防灾减灾工程系,教授

2024- 今 同济大学,结构防灾减灾工程系,长聘教授

研究领域

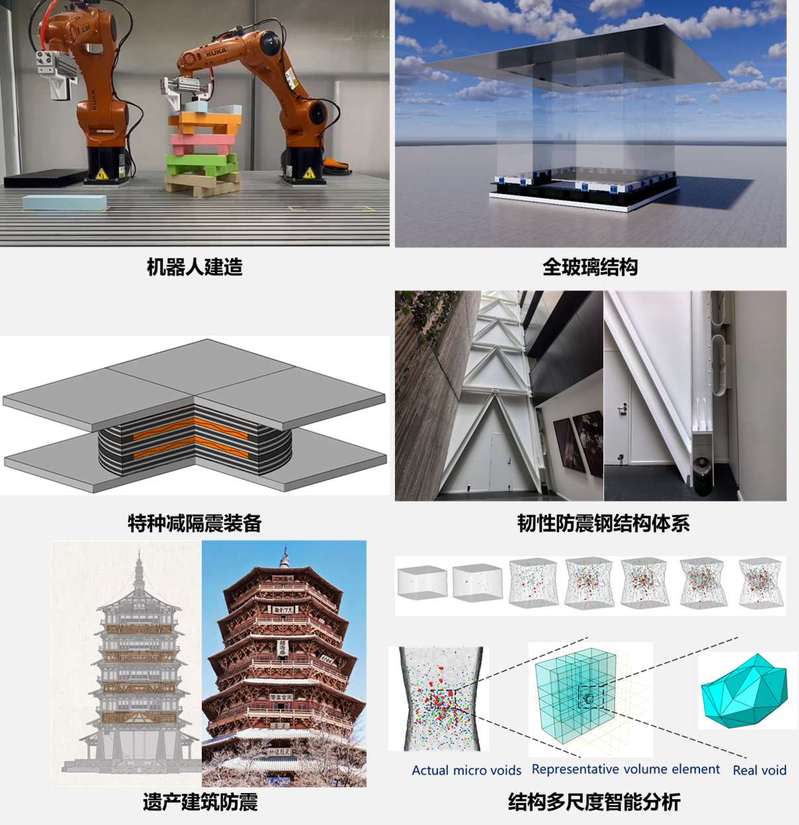

机器人建造

全玻璃结构

特种减隔震装备

韧性防震钢结构

遗产建筑防震

多尺度智能分析

曾获奖励

教育部“长江学者奖励计划”青年学者

中国钢结构协会科学技术奖一等奖

中国钢结构协会科学技术奖特等奖

中国科协首届中国科技青年论坛一等奖

上海科普贡献奖

国际先进材料学会优秀青年科学家奖章

斯坦福全球Top2%科学家

第十二届国际钢结构进展国际会议Young Researcher (Rising Star) Award

国际钢管结构会议CIDECT优秀论文奖

ICE(英国土木工程师学会)最佳论文奖Tso Kung Hsieh Award

地震工程会议优秀会议论文奖

上海市优秀毕业生

同济大学优秀毕业论文

同济大学土木工程学院第一届学生创新赛(SITP)团体第一名

美国土木工程学会东南区学生竞赛钢桥重量奖第二名(团体)

美国土木工程学会东南区学生竞赛挡土墙项目第三名(团体)

日本文部省JASSO奖学金

主要研究项目

上海自主智能无人系统科学中心学科交叉联合攻关首批示范项目,负泊松比超材料宏微观断裂智能预测,2021/8-2022/7,负责人。

上海自主智能无人系统科学中心学科交叉联合攻关第二批示范项目,金属基超材料微观结构与损伤演化的物理信息神经网络,2022/8-2023/7,负责人。

国家自然科学基金面上项目(52478545),韧性全玻摇摆剪力墙结构体系减震机理及其设计方法,2025/1-2028/12,负责人。

国家自然科学基金面上项目(52178499),梁贯通式多重摇摆柱钢支撑框架的减震机理及设计方法,2022/1-2025/12,负责人。

国家自然科学基金青年科学基金项目(51508401),基于微观力学模型不同方式成型圆钢管的屈曲后断裂机制,2016/1-2018/12,负责人

中央高校基本科研业务费专项资金-学科交叉类项目,液压关节机器人控制精度与动态特性研究,2019/1-2020/12,负责人。

ILEE教育部地震工程国际联合实验室国际合作项目,Robust Building System,2018-2022,中方执行人。

东京工业大学国际合作研究项目,金属阻尼器超低周疲劳寿命评估方法,2017/4-2018/3,中方负责人。

国家自然科学基金委员会,国际(地区)合作与交流项目,51820105013,低损伤钢结构体系抗震设计理 论与可恢复性评估系统,2019/1-2023/12,参与。

十三五国家重点研发计划项目,建筑工业化技术标准体系与标准化关键技术,2016/7-2019/12,参与。

十三五国家重点研发计划项目,工业化建筑隔震及消能减震关键技术,2017/7-2020/12,子课题负责人。

中国地震局重点实验室重点专项子课题, 0027020194159, 新型装配式高性能波形耗能棒的耗能机理及其设计方法研究, 2019/9-2022/8,负责人。

中央高校基本科研业务费专项资金-学科交叉类项目(0500219213),钢与超高性能混凝土(UHPC)栓钉连接件的抗剪性能研究,2015/7-2016/12,负责人。中央高校基本科研业务费专项资金-学科交叉类项目,基于装配式栓钉的钢-超高性能混凝土(UHPC)组合构件的应用基础研究(滚动支持),2017/7-2018/12,负责人。

日本文部省基础研究A类(23246097),钢构件的屈曲和破坏的耦合相关研究,2011/01-2015/03,参与。

日本文部省基础研究C类(24560588),含未焊透焊缝钢结构的延性断裂发生相关评价准则的研究,2012/04-2015/03,参与。

日本文部省特别研究员奖励费项目(12F02067),考虑超低周疲劳的桥梁钢结构抗震性能评价方法,2012/12-2013/11,参与。

上海中心加强层关键节点抗震性能试验研究,2010,参与。

2000吨世博轴阳光谷梭形格构柱足尺和缩尺稳定承载力试验,2008,参与。

广州新塔异形关键节点抗震性能试验研究,2007,参与

专著

L-J Jia; HB Ge. Ultra-Low Cycle Fatigue Failure of Metal Structures under Strong Earthquakes. Springer, 2018, ISBN: 978-981-13-2660-8.

贾良玖, 葛汉彬. 强震下金属结构的超低周疲劳破坏, 同济大学出版社, 2019.

代表性期刊论文

In-situ three-dimensional X-ray investigation on micro ductile fracture mechanism of a high-Mn steel with delayed necking effect, Journal of Materials Research and Technology, 24, 2023:1076-1087.

In-situ three-dimensional investigation on micro ductile fracture mechanism of mild steel, Engineering Fracture Mechanics, 283, 2023: 109219.

Effect of boundary conditions on tensile bending strength of glass under four-point bending, Construction and Building Materials, 384, 2023: 131479.

Growth of random polyhedral void in structural steel based on micromechanical RVE simulations, Advances in Engineering Software, 175, 2023:103344.

Theoretical local buckling and bulging analysis on miniature buckling-restrained brace with corrugated core bar, Thin-Walled Structures, 183, 2023:110248.

Shaking table test on single‐story rocking‐column steel frame under excitations along strong axis, Structural Control and Health Monitoring, 29(12), 2022, DOI: 10.1002/stc.3125.

In-plane impact behavior of 3D-printed auxetic stainless honeycombs, Engineering Structures, 266(9), 2022:114656.

Strong axis low-damage performance of rocking column-base joints with asymmetric friction connections. Journal of Constructional Steel Research, 191, 2022:107175.

Shaking table test on a low-damage controlled multiple-rocking-column steel frame, Engineering Structures, 254(5), 2022:113896.

Effect of initial void shape on void growth of structural steels based on micromechanical RVE models, Journal of Materials in Civil Engineering (ASCE), 34(4), 2022:04022010.

Plasticity model for structural steel with Lode angle dependence. Journal of Bridge Engineering (ASCE), 26 (12), 2021:04021087.

Unified full-range plasticity till fracture of meta steel and structural steels, Engineering Fracture Mechanics, 2021.

Dynamic behaviors of steel multiple-rocking-column structural system with rocking stoppers. Engineering Structures, 243, 2021:112649.

Analytical model for local bulging failure of mini-BRBs with circular restraint tubes. Journal of Constructional Steel Research, 183, 2021:106722.

Experimental study on damage detectable brace-type shear fuses, Engineering Structures, 225(26), 2020:111260.

Seismic performance of a single-story articulated steel structure system, Journal of Engineering Mechanics (ASCE), 146(10), 2020:04020108.

Initial studies on brace-type shear fuses. Engineering Structures, 208, 2020:110318.

Dependency of mesh size and loading history on crack propagation energy of cyclic ductile fracture model. Engineering Fracture Mechanics, 215, 2019:117-137.

Resilient steel frames installed with self-centering dual-steel buckling-restrained brace. Journal of Constructional Steel Research, 149, 2018:95-104.

Seismic performance of fish-bone shaped buckling-restrained braces with controlled damage process. Engineering Structures, 169, 2018:141-153.

Constitutive model of aluminum under variable-amplitude cyclic loading and its application to buckling-restrained braces. Journal of Materials in Civil Engineering (ASCE), 30(3), 2018:04017304.

Swing story–lateral force resisting system connected with dampers: novel seismic vibration control system for building structures. Journal of Engineering Mechanics (ASCE), 144(2), 2018:04017159.

Ultra-low cycle fatigue life of aluminum alloy and its prediction using monotonic tension test results. Engineering Fracture Mechanics, 186, 2017:449-465.

Ductile cracking simulation of uncracked high strength steel using an energy approach. Journal of Constructional Steel Research, 138, 2017:117-130.

Push-out tests of demountable headed stud shear connectors in steel-UHPC composite structures. Composite Structures, 170, 2017:69-79.

Ductile-fatigue transition fracture mode of welded T-joints under quasi-static cyclic large plastic strain loading. Engineering Fracture Mechanics, 176(5), 2017:38-60.

Development of a novel high-performance all-steel fish-bone shaped buckling-restrained brace. Engineering Structures, 138, 2017:105-119.

Post-buckling ductile fracture analysis of panel zones in welded steel beam-to-column connections. Journal of Constructional Steel Research, 132, 2017:117-129.

Seismic performance of compact beam–column connections with welding defects in steel bridge piers. Journal of Bridge Engineering (ASCE),22(4), 2017:04016137.

Ductile crack initiation and propagation of structural steels under cyclic combined shear and normal stress loading. Construction and Building Materials, 112, 2016:69-83.

Experimental and numerical study on ductile fracture of structural steels under combined shear and tension. Journal of Bridge Engineering (ASCE), 21(5), 2016:04016008.

Experimental study on cracking of thick-walled welded beam-column connections with incomplete penetration in steel bridge piers. Journal of Bridge Engineering (ASCE), 20(4), 2015:04014072.

Ductile fracture model for structural steel under cyclic large strain loading. Journal of Constructional Steel Research, 106, 2015:110-121.

Integration algorithm for a modified Yoshida-Uemori model to simulate cyclic plasticity in extremely large plastic strain ranges up to fracture. Computers & Structures, 145, 2014:36-46.

Experimental and numerical study of postbuckling ductile fracture of heat-treated SHS stub columns. Journal of Structural Engineering (ASCE), 140(7), 2014:165-180.

Ductile fracture simulation of structural steels under monotonic tension. Journal of Structural Engineering (ASCE), 140(5), 2014:472-482.

Prediction of cyclic behaviors of mild steel at large plastic strain using coupon test results. Journal of Structural Engineering (ASCE), 140(2), 2014:441-454.

若有意向保送或报考防灾减灾与防护工程 或 智能建造 方向硕士生、博士生,请邮件联系,期待和有上进心的同学一起共事。

以下是本人对硕士和博士培养目标的理解

硕士:具有较高科研素养和较深厚专业基础,初步建立科研逻辑思维及方法论,具有解决问题的能力。

博士:具有完整和严密的科研逻辑思维及方法论,具有独立解决问题、发现问题和提出问题的能力。

招聘概况

常年招收国内外优秀博士后研究员

课题组特色

研究方向涉及土木、材料、冶金、大数据、人工智能和机器人等多学科,包括金属材料和结构的多尺度研究、机器人建造、大数据和人工智能算法、新型减隔震结构体系与装备、遗产建筑防震、全玻璃结构、金属基超材料等,与材料、冶金、大数据、人工智能和机器人领域多位青年专家组建了联合攻关团队,期待能为志同道合的博士提供一个安心科研的氛围和平台,有兴趣请邮件联系。

联系地址:上海市四平路1239号同济大学土木大楼B座 电话:021-65982666 传真:021-65982668 邮箱:ddms@tongji.edu.cn 邮编:200092

Copyright © 2018 同济大学土木工程学院结构防灾减灾工程系